From wells to wheels: Seeing the big picture on emissions

Lighter vehicles have lower emissions. But as students in the Advanced Materials Manufacturing program discovered, reducing tailpipe emissions by choosing lighter-weight components can actually increase the overall carbon footprint of vehicles.

Heavier cars burn more fuel and produce more CO2 emissions than their lighter-weight counterparts. With governments around the world enacting legislation to reduce tailpipe emissions, one of the ways the automotive industry has responded is by reducing vehicle weights.

While this is a positive step in reducing tailpipe emissions, an analysis by students in the Master of Engineering Leadership in Advanced Materials Manufacturing shows that the energy consumption and emissions associated with lighter-weight materials can result in vehicles with a higher overall carbon footprint.

As a final project for their class on case studies in materials engineering, seven students examined the embodied energy and emissions of six materials that can be used for automotive wheels.

Historically, steel has been the material of choice for vehicle wheels, but car manufacturers are increasingly choosing lighter materials like aluminum to improve fuel efficiency and reduce emissions.

“In the discipline of materials engineering we tend to focus more on performance than the history and impact of the material,” says Carley Goodreau.

“The goal of our project was to take an in-depth look at the consequences of the materials decisions we make and see if current regulations and legislation with respect to vehicle emissions are doing what they want to achieve.”

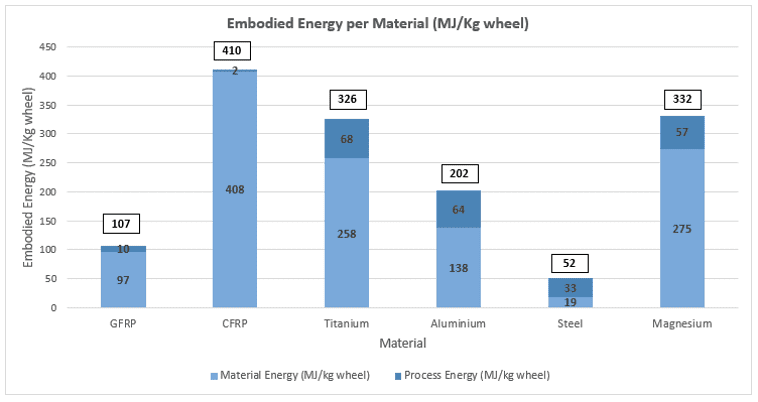

As Chris Gan explains, the students conducted a “well-to-wheel analysis of the energy content and consumption of each step – from extraction to intermediate processing to manufacturing and use. We then determined the embodied energy and CO2 emissions in each material choice.”

The students reviewed six materials that can be used to produce wheels: steel, aluminum, carbon fibre composite, glass fibre composite, titanium and magnesium. For each material, they identified energy consumption and source values from a literature review and industry sources, and then calculated embodied energy, emissions and break-even distances. They also looked at the impact of these material choices on electric vehicles.

As shown in the graph below, each wheel material has specific energy requirements during the extraction and manufacturing process, with steel having the lowest overall embodied energy and carbon fibre composite having the highest:

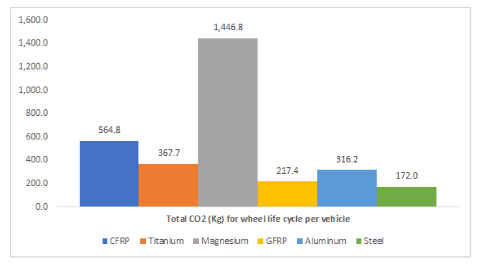

When looking at embodied CO2 emissions, steel once again had the lowest CO2 footprint:

“The results clearly demonstrated that the use of steel would be the best to manufacture the wheels as the total embodied energy of steel wheel is the least,” says Aakarshit Chaudhary.

“Additionally, the carbon emissions from steel wheel manufacturing process and usage was also the least compared to all the other materials and significantly lower than that of electric vehicles.”

The students’ analysis of break-even distances – the point in a vehicle’s life when reduced tailpipe emissions offset the emissions created in manufacturing its lighter wheels – allowed them to analyze the true environmental impact of each material choice.

As they state in the summary of their project report: “For most materials, the break-even distance will not be reached within the useful life of the vehicle…. Replacing steel wheels with other lightweight materials does not necessarily result in net energy or emission savings of the vehicle throughout its useful life. Creating standards that force vehicle manufacturers to reduce weight to meet GHG emissions requirements does not provide the environmental benefit intended when a full life-cycle analysis of each material is conducted.”

As they note, for those materials that do have favourable low embodied energies and emissions, like glass fibre composite, there are important performance concerns as well as the added issue that the material is not easily recyclable at the end of its life.

“As has been proven by the results of this study, a focus on tailpipe emissions does not take into account the emissions that went into the production phase,” says Upjeet Brar. “Incomplete analysis results in adding an emission burden to the environment while we falsely console ourselves that we are saving it.”

None of the students had conducted this type of life-cycle analysis before taking the class. As a result of the project, they now say they have a new appreciation of the importance of doing a holistic assessment of the impact of material choices.

“I’ve been involved in vehicle design for four years and helped launch two products, but I’d never before considered the full life-cycle impact of material selection,” says Sangeeth Karuppiah.

“Going forward I will definitely look into the embodied energy and CO2 emissions when selecting materials.”

Like Sangeeth, Maryam Khodabakhsh Pirkalani also came to the program with a background in the automotive industry.

“Finding ways to lighten vehicle weights – and thereby reduce CO2 emissions – has been a priority for the organizations I worked for, with companies going so far as to pay more for aluminum,” she says. “My attitude toward this approach has broadened and changed.”

The challenge, say the students, is that automotive industry regulations focus only on tailpipe emissions rather than a full life-cycle analysis of the embodied energy and emissions within the vehicle itself. Ideally, policy and regulations will catch up with the science – but that will require more full-scope studies and analysis, as well as the political will to take a broader perspective.

In the meantime, manufacturers should consider conducting a life-cycle analysis of potential materials to help them make decisions based on a range of factors.

“Products with low embodied energy and CO2 emissions could provide a competitive advantage in some industries and markets,” says Felipe Blanco.

“A life-cycle analysis offers important information for making investment decisions, and it could be significant for governments, when planning public policy. For example, they could provide investment incentives to the manufacturing industry at locations with lower emissions rates, thereby contributing to local economic development.”

Application Deadlines

The online application portal for the January 2025 has closed.

Get ready to apply!

Admissions for the 2026 intake will open on January 1, 2025.

How to ApplyAssess your Eligibility

Determine if your professional experience and academic background make you a fit for your desired program.

Start AssessmentJoin us for an

Info Session

Sign up for our latest online information sessions and discover what our programs have to offer.

Sign Up NowAdvanced Materials Manufacturing

Develop new technical and business skills and accelerate your career in this rapidly moving field.

Read More