Bringing machine learning to composite materials manufacturing

Advanced Materials Manufacturing: Bringing machine learning to composite materials manufacturing

By Casey Keulen, Assistant Professor of Teaching in the Department of Materials Engineering and program director of the MEL in Advanced Materials Manufacturing

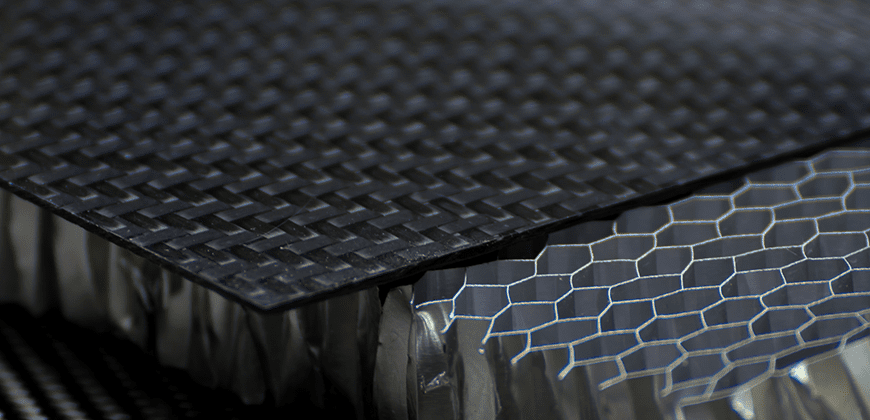

Composite materials and structures are playing an increasingly important role in our world, transforming a range of industries like aerospace and green energy. By applying digital manufacturing and machine learning to materials processing, engineers are addressing some of the more complex challenges associated with processing these innovative materials.

Composites offer significant advantages over conventional metals, allowing for incredible flexibility in design and function. In the case of the aerospace industry, for example, composite components are being used to create lighter aircraft that burn less fuel and fly faster. With its all carbon-fibre construction, the Boeing 787’s cabin can be maintained at higher pressure and humidity levels than traditional aircraft, resulting in a more pleasant passenger experience. The engineering behind the Boeing 787 fuselage and the Boeing 777X wing emerged out of process simulation work done at UBC’s Composites Research Network, where researchers have a long history of working at the forefront of the field.

However, there are many inherent challenges when manufacturing composite structures, not the least because you are making both the material and the part at the same time. These challenges include processing defects such as porosity, residual stress and dimensional control.

Machine learning offers one strategy to address these complexities. However, composite materials manufacturing lags other industries in that we don’t have access to the massive data sets commonly required to support machine learning. Theory-guided machine learning – blending classic engineering science theory with modern machine learning – is a promising alternative for developing machine learning algorithms for applications in aerospace that is being researched.

Students in the Master of Engineering Leadership in Advanced Materials Manufacturing program dive into these concepts in their engineering courses under the guidance of leading researchers.

They graduate with upgraded engineering skills and knowledge of the latest advances in composite materials, intelligent manufacturing and simulation software. Our program is grounded in case studies and project work, enabling our students to learn from real-world manufacturing issues.

The program’s business and leadership classes complement this technical focus. Many students come to the program at that point in their professional careers where they are wanting to take the next step into management and leadership roles. The training they receive through the business and leadership classes helps them to confidently make that shift.

UBC is an exciting place to pursue this work. Our undergraduate degree in manufacturing engineering is now in its third year, and we are in the process of building new facilities and have recently hired four professors with wide-ranging expertise in composites, metallurgy and biomaterials.

MEL students benefit from this synergy and have access to courses offered through the undergraduate program, including a recent addition on intelligent manufacturing.

Advanced Materials Manufacturing

Develop new technical and business skills and accelerate your career in this rapidly moving field.

Read MoreFeatured Faculty and Staff

DR. CASEY KEULEN

Join us for an

Info Session

Sign up for our latest online information sessions and discover what our programs have to offer.

Sign Up NowFeatured Alumni

Liam Russell

With a uniquely multidisciplinary skill set that includes a deep understanding of materials engineering as well as foundational knowledge of business and leadership, Liam is pursuing opportunities to develop next-generation sustainable advances in the manufacturing sector.