Learning the Business Aspects of Chemical Processes

It’s a complex process to take an idea for an innovative technology from that initial eureka moment to full on commercialization. Success depends on a specific set of skills, a solid understanding of the development and commercialization approach required, and an integrated appreciation of the distinct phases of process development and scale-up, both from a business and technical perspective – and all of this must be adapted to the specific technology and industry.

Recognizing that there was a gap in professional training in the specific area of technology development for chemical and biological industrial processes, which are both at the core of sustainability processes, Sergio Berretta developed “Technology Commercialization for the Manufacturing Industries,” a course designed specifically for UBC’s Master of Engineering Leadership (MEL) in Sustainable Process Engineering program.

“On the technical side, technology development in the chemical and biological process industries is an area of knowledge that has received little attention, in large part because it is poorly understood,” says Berretta. “In general, we associate technology development as research and design activities, but development falls in between these activities, eventually integrating design. Development is what ties it all together.”

“In other courses within the program, our students learn about the business aspects of process development and commercialization, so in this course we wanted to focus on the technical aspects and challenges that they’ll face when moving process technologies from the idea phase through to commercial implementation.”

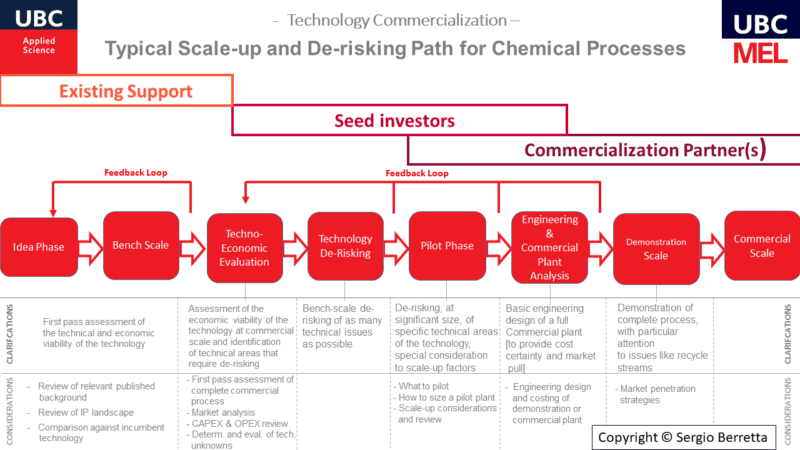

As Berretta points out, there is a tendency to talk about “R&D” as though research and development were a single activity. “These are distinctly different areas of practice,” he says. “Research is about discovery, whereas development is about moving that discovery from the bench through a number of integrated development phases, such as techno-economic reviews, scale-up analyses, pilot operations and translation of development results into engineering design terminology, all of it followed by the full design of a demonstration or commercial process plant. Working through this process proficiently requires a wide range of knowledge.”

The absence or poor grasp of this knowledge can have significant implications.

Over his three decades in the chemical industry (including as head of BC Research, a process technology scale-up and commercialization centre), Berretta has seen many start-ups and medium-size companies involved in the development of process technologies run out of time and/or money, many times stalling at the pilot plant stage.

Yet in some cases, the processes or technologies these companies were working to commercialize had solid foundations and the potential to change our world for the better – whether through improved efficiencies to produce chemical compounds or the large-scale commercialization of technologies that might help us to economically capture carbon, produce hydrogen or create products using biomass rather than fossil fuels.

Over the four-month course, students complete a case study of an actual industrial development project from the idea phase through to commercial implementation.

In 2021, the students are analyzing a process technology to produce spirulina (a blue-green algae with strong antioxidant properties) using bioreactors that absorb discharged carbon dioxide emissions from breweries, potentially making this a carbon-negative technology.

Throughout the course, students also complete shorter assignments where they apply what they are learning in class to solve a defined technical and economic challenge for an industrial process currently under development or consideration, pulling from Berretta’s own experience or that of his colleagues in industry.

The objective is that students in the MEL in SPE program will complete the course with a broader and deeper understanding of the technical phases and work involved in developing and commercializing process technologies, giving them the skills to collaborate or supervise the research engineers involved at the start of the development process and the design engineers involved at the end of the development cycle. The course also covers other relevant content – from intellectual property strategies for protecting the development work to market penetration strategies for diverse process innovations.

“Our students need to know what it takes to get process technologies into the market,” says Berretta. “This course enables them to truly understand the technical and economic challenges that are part of that process.”

Sustainable Process Engineering

Translate innovations in green chemistry and sustainable manufacturing into entrepreneurial ventures.

Read MoreFeatured Faculty and Staff

Dr. Amy Kim

Join us for an

Info Session

Sign up for our latest online information sessions and discover what our programs have to offer.

Sign Up NowAssess your Eligibility

Determine if your professional experience and academic background make you a fit for your desired program.

Start Assessment