Assessing the viability of carbon capture technology

Tommy Holt and his classmates conducted a streamlined life-cycle analysis of using captured CO2 emissions from a hypothetical brewery in Alberta to produce algae-based animal feed. Their conclusion? When it comes to carbon capture technology, location matters.

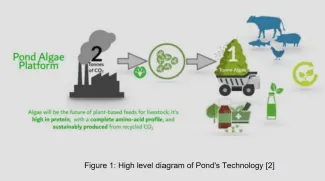

In 2024, students in the Master of Engineering Leadership in Sustainable Process Engineering program worked directly with developers of carbon capture technologies to assess potential use cases. Tommy Holt was part of a team that worked with a green technology supplier that has developed bioreactors that turn carbon dioxide into algae and other commercially valuable products.

We were asked to assess the business/environmental case for a hypothetical project using the company’s technology.

“We analyzed the environmental impact of capturing carbon dioxide emitted from a hypothetical brewery located in Alberta and using it as a feedstock to grow protein-rich algae that could then be sold as animal feed. Along with exploring the technical elements, we also looked at the broader policy framework,” said Tommy.

The emissions produced during the brewing process are currently released to the atmosphere. However, they can be captured by algae and potentially transformed into value-added products like nutraceuticals, animal feed and biofuels.

The group’s analysis showed that the company’s bioreactors could capture 2.6 tonnes of carbon dioxide for every 100,000 litres of beer produced by the brewery. That’s a significant amount given the average Canadian’s annual carbon footprint is around 17.5 metric tonnes of carbon dioxide.

The students then conducted a streamlined life-cycle assessment of two distinct scenarios to quantify the environmental impacts in terms of global warming potential: gate-to-gate (where the algae-based animal feed is produced and delivered the customer, but not consumed) and gate-to grave (where the algae is consumed as animal feedstock).

This is where things got complicated: because the brewery is located in Alberta in a facility that would be using electricity generated from a power plant fuelled by natural gas, the process would ultimately emit more carbon dioxide emissions than what could be captured from the company’s technology.

For the gate-to-gate scenario, 22.6 kilograms of carbon dioxide equivalent are produced for every 100 litres of beer, and for the gate-to-grave scenario, 25.2 kilograms of carbon dioxide equivalent are produced for every 100 litres– a higher number as the captured emissions are returned to the atmosphere by the animals who have consumed the algae-based product.

Regardless of the scenario, the emissions almost all derive from emissions associated with generating the electricity needed by the bioreactor.

As Tommy notes, if the project was located in British Columbia or another province with an energy grid dominated by renewable energy, the outcome of the analysis would be entirely different and the process would have a net environmental benefit.

The group also looked at the broader policy framework. Breweries are not subject to the carbon tax for emissions generated through the brewing process, and as such, there is no financial incentive for them to reduce these emissions or capture them for use in other products.

One of the takeaways of this project and the course as a whole was just how challenging decarbonization is, and how important vigilant analysis is in assessing new technologies as results can easily be manipulated to create misleading conclusions.

“You need to look at the big picture and you need to have the technical and economic analytical skills to be able to carefully analyze solutions to ensure they are achieving the desired impact,” he says.

Using his entrepreneurial and engineering skills to make a difference

Tommy came to the MEL with extensive experience in engineering, hardware development and program management. He appreciated the program’s mix of technically focused courses in sustainability-sector-based topics and MBA-style courses in business topics, seeing it as a potential pathway to pivot towards a career in business development, product management or strategy in the carbon capture space.

He further honed his business skills – and grew his network – through his involvement with the Creative Destruction Lab, a startup accelerator for early-stage science-based companies. Students work directly with startups on various aspects of business development, and Tommy had the opportunity to collaborate with three different startups on market analysis, partner identification and competitive and differentiation analysis.

Looking back on his master’s degree, Tommy says the course on carbon capture and storage was a definite highlight.

This particular course was very good at highlighting how professionals in this space can apply their skills and the types of work they can do to advance the sector and address the challenges of climate change.